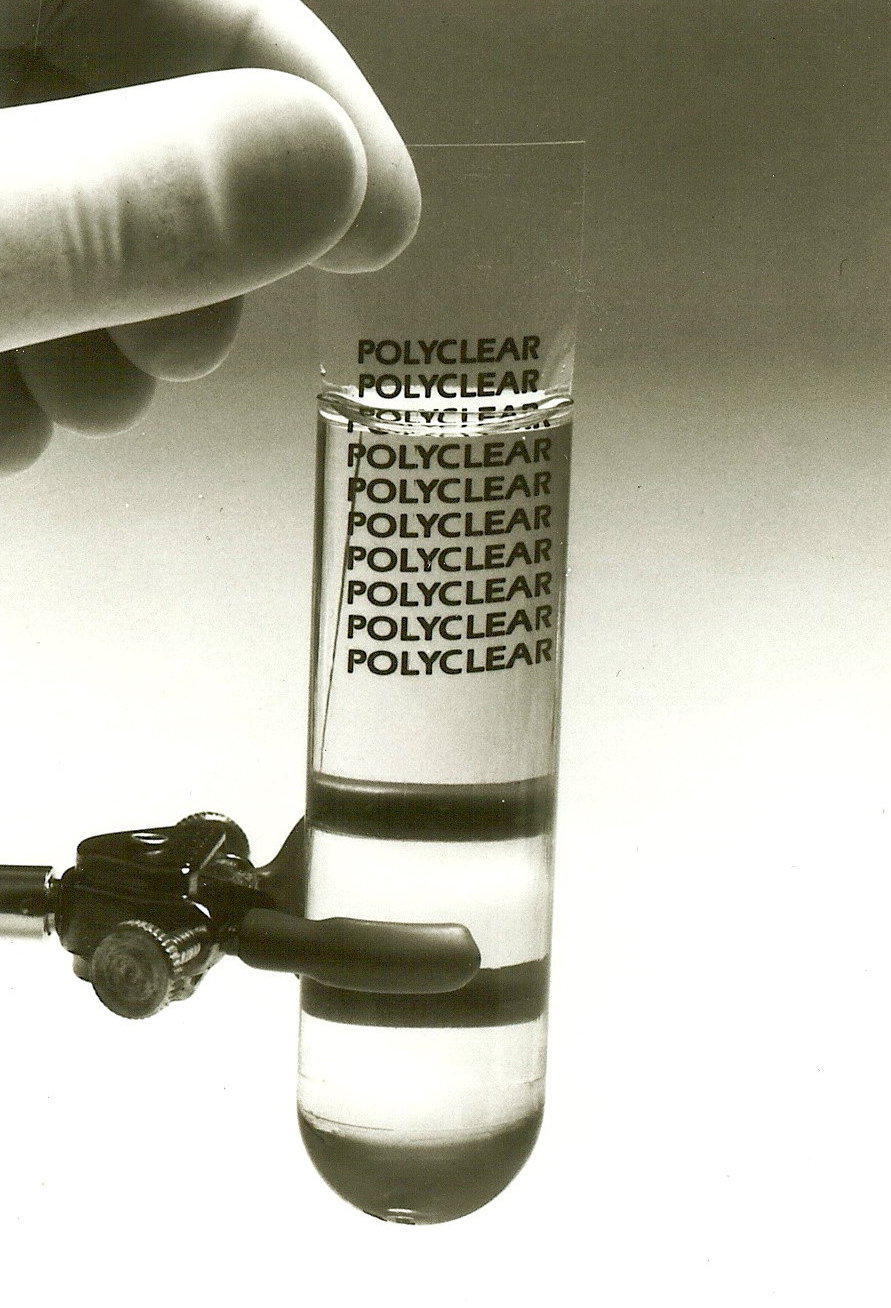

Polyclear thermoplastic is transparent and non-wettable in an uncoated state. The UltraCote layer applied to Polyclear tubes provides a wettable surface for convenient gradient formation. See UltraCote Tubes. Thin wall Polyclear tubes are puncturable but generally with more effort than polyallomer tubes. UltraThin tubes made of the Polyclear material are about one-half the side wall thickness of open-top Polyclear tubes and are significantly easier to puncture. See UltraThin Tubes. The useful centrifuge temperature range is 0-20 deg. C. Polyclear tubes can be used at temperatures greater than 20 deg. C, i.e. 25 deg. C, but they may be difficult to extract from the rotor. You may have to wait for up to 5 minutes to smoothly extract the tubes. The ability to extract depends on the length of run, temperature, fluid and rotor. Generally, the longer, warmer and faster the run, the greater the required effort to extract the tubes. However, at temperatures up to 20 deg. C, the effort should not be significant. The chemical resistance of Polyclear is not as good as polyallomer, and resistance to solvents at centrifuge stresses is poor. Mineral and paraffin oil overlays should not be used as they may cause significant crazing during the run. Polyclear can be used up to a pH of 8.5. Generally the longer and warmer the run, the greater the effect of gradient pH. Sterilization can be achieved by treatment with ethylene oxide gas or by cold methods (1).

See Chemical Resistance

(1) Aqueous solutions of 70% ethanol, 70% isopropanol or 10% hydrogen peroxide.

*Trademark of Beckman-Coulter Instruments, Inc.