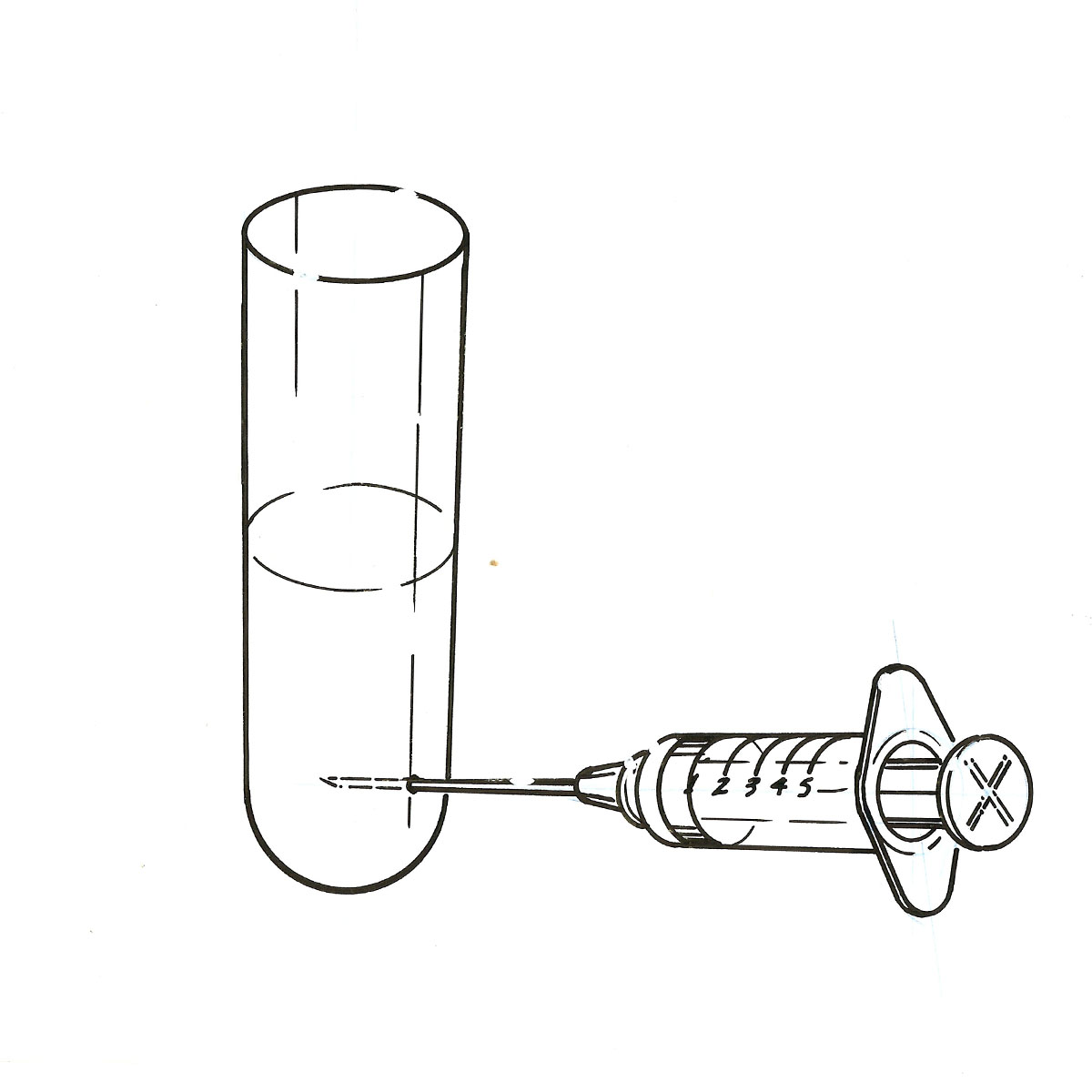

UltraThin tubes are made with thin side walls for easy puncturing and slicing after swinging bucket runs (1). These extremely thin, yet durable, Polyclear tubes can be used in the 0-20 deg. C temperature range at maximum rotor speeds and gradient densities. UltraThin tubes are manufactured with precise process controls and provide straight walls with excellent transparency. Because of the thin walls, UltraThin tubes provide increased tube/rotor volume over conventional thin wall tubes. UltraThin tubes are also available with the wettable UltraCote layer applied allowing gradients to be easily formed. See UltraCote Tubes. The extremely thin walls, wettability and transparency combine features not available since the discontinuation of cellulose nitrate tubes in 1980. The chemical resistance of UltraThin tubes is the same as that of conventional Polyclear tubes and is described on Chemical Resistance. To provide maximum wall support, fill the tubes to within 2-3 mm of the top.

CAUTION

+ Do not autoclave UltraThin tubes

+ Do not use UltraThin tubes with oil overlays or solvents

+ Fill the tube to within 2-3 mm of the top

(1) UltraThin tubes are about one-half the side wall thickness of conventional thin wall Polyclear and Ultra-Clear tubes. However, the center bottom thickness in a region about one-half the tube diameter is not as thin as the side walls.